Set up and retrieve inspection grids from thickness gages fast and easy.

Track tank thickness inspection measurements and provide calculation reports. INSPECT’s fatigue assessment scans the vessel for other flaw types and allows the user to adjust the “remaining strength factor” (RSF) as required by API 579.Īddress in-service activities such as inspection, remaining life determination and repair.ģD inspection data management and calculations simplify compliance with the requirements of the API-570 Code. Model laminations and provide rapid results so you can make the necessary mediation decisions with confidence Level 1 and 2 dent, gouge and dent-gouge combinations are available. Perform Part 12 assessments and generate detailed API 579 reports. Perform fire damage assessments and document conclusions in a consistent series of data entries and reports.

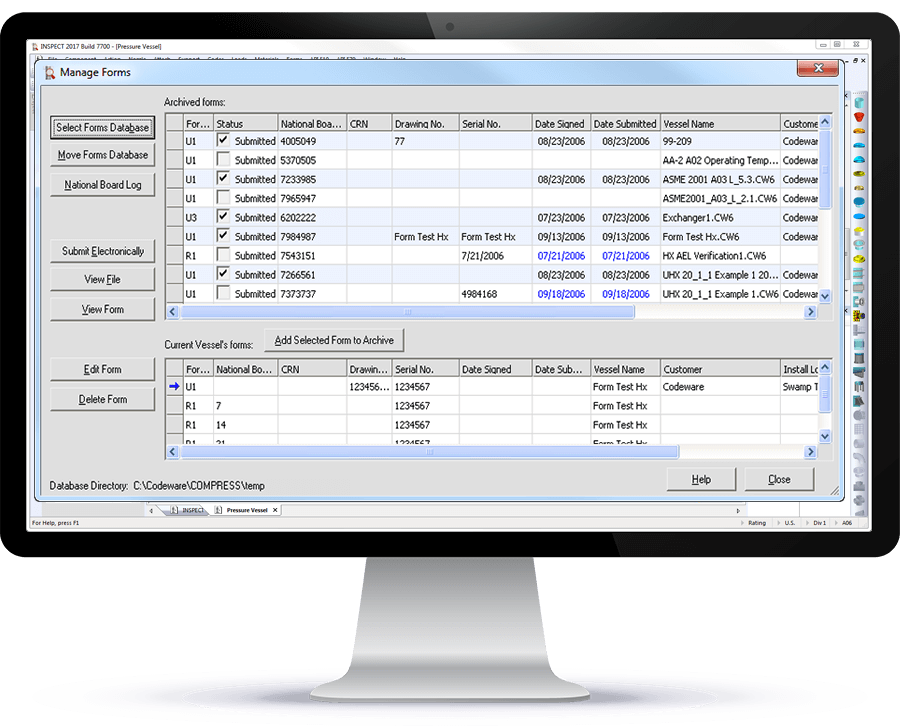

Perform creep damage assessments by recording equipment operating histories and calculations. Level 1 and 2 assessments quickly determine which crack-like flaws can be safely left in service and which require more investigation. Perform Level 1 and 2 assessments from Hydrogen Induced Cracking (HIC) and Hydrogen Blister damage.Įnsure that vessels subject to external pressure are within the allowed roundness tolerance with out-of-roundness assessments. INSPECT performs level 1, 2 and 3 pitting assessments and generates detailed API 579 reports with a click of a button. Perform general and local metal loss assessments and quickly generate detailed reports. It includes all available COMPRESS functionality and shares the same easy to use interface and file format.Įnsure your operating procedures limit the risk of brittle fracture by automatically running Part 3 assessments. INSPECT is a Fitness-For-Service extension of our market leading COMPRESS pressure vessel software. INSPECT’s integration with Shopfloor helps you document welding repairs as well. INSPECT performs rigorous t min calculations that can extend vessel remaining life and inspection intervals. It also organizes and adds context to your inspection data by showing CML’s and API 579 flaws on its 3D equipment models.ĭepending on your needs, INSPECT’s API 579 FFS can assess individual components, complete vessels, or model entire process systems. INSPECT Fitness-For-Service Software reduces regulatory compliance risk by creating ASME design reports for your undocumented pressure vessels. It creates detailed Fitness-For-Service (FFS) reports for pressure vessels, heat exchangers, piping, and above ground storage tanks.

INSPECT performs the calculations and assessments needed by Engineers engaged in process plant inspection and maintenance activities.

0 kommentar(er)

0 kommentar(er)